How to Insulate a Car to Make it Quiet - Expert Knowledge - A-Z with Sound Insulations Ltd

On this page you will find free insulation advice for insulating classic cars, SUV's and individual components all made easy with expert advice from industry professionals.

Where to begin when insulating a car?

Many clients ask us this when starting a car insulation project! We believe that knowledge gathering is the first port of call for understanding how and when to start your car insulation project (here we hope you will find this car insulation advice and knowledge).

After initial knowledge gathering for your car insulation project, we then recommend creating a brief of the end result you are looking for when you complete your car insulation project. This could include and not be limited to the following questions and answers.

Which of the various car insulation products available on the market would I like to fit to my car?

Do all the car insulation products perform the same job?

Which areas of the vehicle are easy to insulate thermally and acoustically, which areas are difficult?

How refined would I like my car after it has been insulated?

We hope to cover all of the above questions in the following car insulation guide by area of the vehicle, along the way we will advise on potential materials which maybe fitted to the certain areas of the vehicle.

CAR INSULATION GUIDE 2025 by Sound Insulations Ltd

Within this guide we will rate the complexity of insulating each application on a scale of 1 - 10 to assist you when looking for areas of the car you are looking to insulate.

We will start our car insulation guide at the front of the car and work towards the rear of the car.

Front Bulkhead (Outer) Insulation:

Difficulty: 10 / 10

Reason: Usually this requires the engine to be removed

Tips: When fitting the front bulkhead (engine side) insulation it is beneficial to take measurements for material thickness prior to the engine being removed. You can then mark up the areas where a thicker product can be fitted. It is also important to note any hot areas of the engine system and ensure that heat managment products are used in these areas to ensure a safe, quality finish.

Material suggestions:

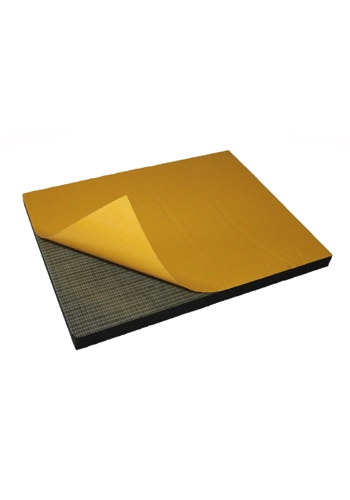

For the front (outer) bulkhead insulation the packaging space usually denotes the insulation to be fitted within the application. We suggest firstly you insulate with our ButylMAT material (recommended max temp 90 C) this will offer you sound deadening, a reduction in panel resonance as well as a barrier type layer to reduce sound transmission.

If space allows in areas you can use our Class 0 Closed Cell Foam Insulation material manufactured out of PVC Nitrile. It is water resistant and flame retardant to Class 0. You can also locally apply our glass fiber heat insulation material which can withstand at its core 500 C.

ButylMAT

Glass Fiber Heat Reflective Insulation For Engine Bay Areas

PVC Nitrile Outer Bulkhead Car Insulation

Hood or Bonnet Insulation:

Difficulty: 5 / 10

Reason: Usually a fairly simple task which offers great results with the right products

Tips: When fitting the hood or bonnet insulation materials it is ideal to template the areas within the recesses using card, paper or stiff polyester templating material.

Material suggestions:

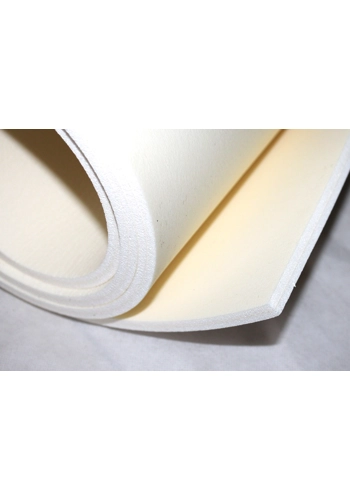

For the bonnet insulation the packaging space usually denotes the insulation to be fitted within the application. We suggest firstly you insulate with our ButylMAT material (recommended max temp 90 C) this will offer you sound deadening, a reduction in panel resonance as well as a barrier type layer to reduce sound transmission. Then you can use either our Class 0 Closed Cell Foam (PVC Nitrile) or our SIOPCELL foam (open cell) The SIOPCELL will absorb the noises within the engine bay area and really reduce sound transmission from the engine to the rest of the vehicle as you are targeting the noise issue at source.

SIOPCELL Bonnet Liner Foam Insulation

SIOPCELL Datasheet and Test Specification

Interior Bulkhead Insulation:

Difficulty: 8 / 10

Reason: Usually this requires the dashboard to be removed

Tips: When fitting the front bulkhead (cabin side) insulation it is beneficial to take measurements for material thickness after the dash has been removed. You can then mark up the areas where a thicker product can be fitted. You can also look to fit a compressible product for ease of fitment when you look to refit the dash console.

Material suggestions:

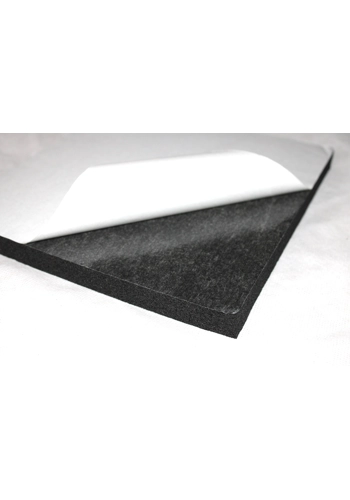

For the inner bulkhead insulation the packaging space usually denotes the insulation to be fitted within the application. We suggest firstly you insulate with our ButylMAT material, this will offer you sound deadening, a reduction in panel resonance as well as a barrier type layer to reduce sound transmission. Then you can look to use either our VBLAM23 (23mm MLV/Polyester laminate) or our SIOPCELL Open Cell Foam Insulation (space allowing) If space is not allowing the thickness of these car insulation products (please note they are compressible to around 50%) then we recommend you fit the MLV component of the VBLAM which is DECILAM. This high performance mass loaded vinyl car insulation material is only 3mm thick and offers 27dB sound reduction properties.

VBLAM23 Sound Deadening Laminate For Bulkhead and Car Interiors

DECILAM Vehicle Interior Insulation & Sound Deadening

Door Insulation (Wet Side & Dry Side):

(Wet Side Car Door Insulation)

(Dry Side Car Door Insulation)

Difficulty: 6 / 10 (Dry Side) 8/10 (Wet Side)

Reason: Usually this requires the door card to be removed for the dry side and the car door insulation then fitted. For the wet side we suggest you remove the inner door card or plastic membrane (with the window in the upright position)

Tips: When fitting the dry side door insulation ensure the material clears the plastic clip fixing areas and ensure the material you use is compressible enough for this application. For the wet side door insulation it is advisable to use a hydrophobic insulation material such as Thinsulate.

Material suggestions:

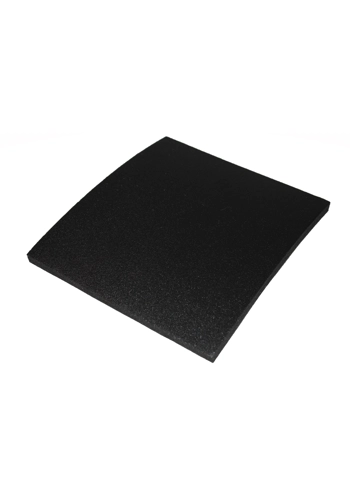

For the dry side door insulation we do a 20mm or 30mm SIFELT material which is used by car manufacturers in this area (details below). For the wet side car door insulation you can use ButylMAT onto the metal panels to stop or reduce panel resonance, followed by Thinsulate in these areas (space allowing)

SIFELT Dry Side Car Door Insulation (Available in 20mm and 30mm Thickness)

Thinsulate Wet Side Car Door Insulation

Under Carpet and Tunnel Insulation for Cars:

Difficulty: 9 / 10

Reason: Usually this requires the seats and centre console to be removed.

Tips: When fitting under carpet insulation it is important to build layers of insulation to ensure you have a flat section under the carpet. You can use materials which have adhesive backing for ease of fitment. Measure the existing carpet thickness and gauge what you can confortably package (in thickness) within the carpet well. For over the car tunnel insulation you can take templates using paper, card or similar to gain the correct shape and manipulate the material to fit using perforation cuts in the material along the lines needed to be folded.

Material suggestions:

Again, for the under carpet it really depends on the geometry. You are more than welcome to whatsapp us or email pictures for specific carpet insulation advice for cars. That said, however, we would suggest an absorption layer followed by a barrier layer. So if you look in further detail at our DeciLAM material as the barrier and either our SIFELT or SIOPCELL Foam as the absorption layer.

For the tunnel you may want to look at using our high performance laminate VBLAM23 or VBLAM33 to provide exceptional sound insulation properties. (all of the above products can be seen above)

Car Under Seat Insulation:

Difficulty: 5 / 10

Reason: Usually this requires the rear seat squab to be removed.

Tips: When fitting under seat insulation into a vehicle you will first have to remove the seat squab which is usually fairly straightforward.

Material suggestions:

Due to space constraints and the seat itself being an absorbing product, we suggest using a product such as ButylMAT insulation to fit into this appllcation as it is only 1.7mm thick and very effective at noise control. The seat will absorb the other noise from the exhaust and wheels.

Wheel Arch Insulation for Cars:

Difficulty: 7 / 10

Reason: Usually this requires the plastic or composite wheel arch liners to be removed.

Tips: When fitting absorption products to wheel arch liners of cars it is important to remember for ease of fitment it is how much of the insulation product is fitted, it's density and absorption characteristics as to the performance you will achieve.

Material suggestions:

For insulating an outer wheel arch liner we recommend using a hydrophobic insulation material such as Thinsulate as this will benefit you by not absorbing water within this area. It is very compressible and self adhesive for ease of fitment.

Boot Insulation for Cars:

Difficulty: 6 / 10

Reason: Usually this requires the rear trim and spare wheel to be removed. Some cars suffer with a rear openness which causes a lot of reverberant noise appearing to come from the rear of the vehicle. To combat this simply remove the trim and fit the boot insulation products below.

Tips: When fitting boot insulation it is important to cover the area on top of the exhaust (if applicable) with the most product to ensure you get the best value for money from the material.

Material suggestions:

For the rear boot area you can usually fit ButylMAT to cover the boot area under the plastic trim directly on to the metal body panels. This can then be followed by SIFELT or Thinsulate dependant upon the space you have within the boot area.

ButylMAT Sound Deadening for Car Boot Insulation

SIFELT Car Boot Insulation Material

We hope you have enjoyed reading our guide for Car Insulation 2025. Please do not hesitate to send us pictures of your project over whatsapp or email for us to advise you further on car specific insulation applications.

Please telephone us on 07513360708 if you require further car insulation advice or have another application you are thinking to use our vast insulation product range within.